5 Things You Didn’t Know About Configurators

Authored By: Megan Marsh

As product configurators become more popular in the manufacturing industry, here are 5 new things to learn about this tool:

1. Everyone is a Sales Expert

Using a Product Configurator and Dealer Portal software as a manufacturer can support the onboarding of new employees in several ways:

Standardization: Using a product configurator provides a standardized process for creating quotes and proposals, which helps new employees learn the process quickly and easily. It ensures that all quotes and proposals are consistent, accurate, and comply with company policies and procedures.

Centralized Database: A product configurator also stores all product information, pricing, and configurations in a centralized database, making it easy for new employees to access and understand the information. This eliminates the need for manual data entry, reducing the chances of errors and improving the overall efficiency of the onboarding process.

Automated Workflows: A configurator software streamlines the quoting and proposal process by automating workflows. This eliminates the need for new employees to manually create quotes and proposals, reducing the learning curve and improving productivity.

Training Materials: Many Configurator Sales Portals provide a place to store training materials, such as video tutorials and user guides, which can be used to onboard new employees quickly and efficiently. This allows them to learn the software, products, and features at their own pace.

In short, using a configuration software as a manufacturer can help new employees onboard faster, reduce errors, and improve productivity. It provides a standardized process for creating quotes and proposals, a centralized database for product information, pricing, and configurations, automated workflows, and training materials virtually stored to help employees learn the products quickly and easily.

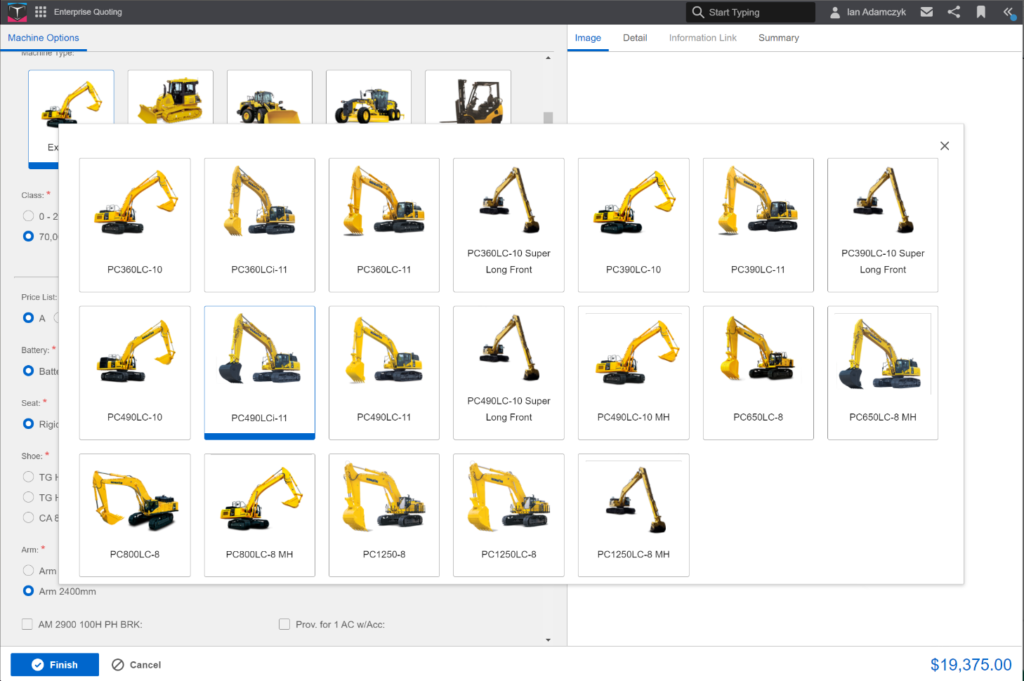

2. You Can Configure Anything

Whether it be semi-configurable parts, assemble-to-order, or fully custom, any product can be added to the system. Product lines and parts are not the only thing to add; users can configure anything with the right setup.

Manufacturers can add contracts and items to create customized documents based on customer needs. And users can add and configure different service requests to quotes. This allows the sales team to include all necessary information and requests in one location.

3. Part Sales Are Always Managed

Catalog management: Manufacturers can use a configurator with a dealer portal to manage their product catalogs and configure them based on specific customer needs. They can define product attributes such as size, color, material, pricing options, and configure the parts accordingly or select non-configurable and spare parts additions.

Pricing and discount management: Manufacturers can use configurator software to manage their pricing and discounts for parts. They can define pricing rules based on different customer segments, geographic regions, or volume discounts. They can also define discounts for specific parts based on promotions or customer-specific pricing agreements.

Overall, a robust product configurator provides manufacturers with a powerful tool to manage part sales. It enables them to configure parts based on customer needs, manage pricing and discounts, and generate full quotes and proposals quickly. This can help manufacturers improve their sales processes, increase efficiency, and provide a better customer experience.

4. A Product Configurator Supports the Customer’s Experience

In fact, If you don’t provide a customer experience that they expect, 89% of consumers will switch to a competitor. Now what does the modern day consumer expect? Customer’s expect a fast quote and ordering experience. If a dealer or sales rep does not provide a quote in a timely manner or doesn’t provide accurate information they will find a competitor that will. Consumers expect organized documentation and delivery of those items. If the proposal and ordering process is too confusing you will lose them to someone with a seamless workflow.

This is why it is so important to enable your sales and dealer team to quickly create quotes and proposals that are tailored to the customer’s needs. They need to be able to quickly generate accurate quotes for parts based on the customer’s configuration. When given a configurator and sales tools users can automatically calculate pricing based on the configured parts and apply any relevant discounts. This allows the sales team to create quotes and proposals quickly, improving the overall sales cycle.

5. Pulling Outside Data is Simpler Than You Thought

Not all product configurators are system agnostic – meaning that the technology can work independently of any specific system. This is a key benefit to systems compatibility and can be found with configurators like, Infor CPQ for example. When using an agnostic product configurator manufacturers can be confident in the ability to integrate any system. Pull customer, part, pricing, routing information and more into your configurator from your other enterprise systems like a CRM or ERP. Overall, a system-agnostic approach can provide greater flexibility, compatibility, and scalability, as it allows technology solutions to work seamlessly across various platforms and devices.

Product configurators and dealer portals are growing in popularity due to the rising need for higher productivity. These tools eliminate bottlenecks in the sales cycle, allowing customers to see the right product, at the right time and at the right cost.

Thanks for reading. Need some support in your product configurator research? With over 15 years of experience in the manufacturing industry, RenaissanceTech will answer any additional configurator questions you have. Talk to us today!